Smart Gateway

Data Tranfer Unit (DTU)

Ethernet Communication

CE Certificated

Downstream RS485 Communication

Max. Access 25 Devices

Optional Power Supply

Smart Gateway

Data Tranfer Unit (DTU)

Ethernet Communication

CE Certificated

Downstream RS485 Communication

Max. Access 25 Devices

Optional Power Supply

24 Channels Temperature Measurement

Support PT100/PT1000/NTC Sensors

High Accuracy Class 1

2 Channels Alarm Outputs

RS485 Communication

Rated Current: 80A Direct Input

Bulit-in Relay

For Prepaid/Postpaid Billing System

4G Communication

4 Tariff Rates

RS485 Communication

8 Channels Temperature Measurement

Support NTC,PT100/PT1000 ,Thermocouple Sensors

High Accuracy Class 1

5 Channels Alarm output,3 Channels 4-20mA Output

RS485 Communication

IEC61000-4-30 Ed3 Class A Certificate

IEC61850 Communication Protocol

2nd ~ 31rd Harmonics Measurement

Disturbance Waveform Recording

2000+ Waveform Recording

5000+ SOE Recording

Wireless Comm. 4G

Input Current 5A/1A(Via CTS ) or mV(Via Rogowski Coil )

Phase-sequence correction

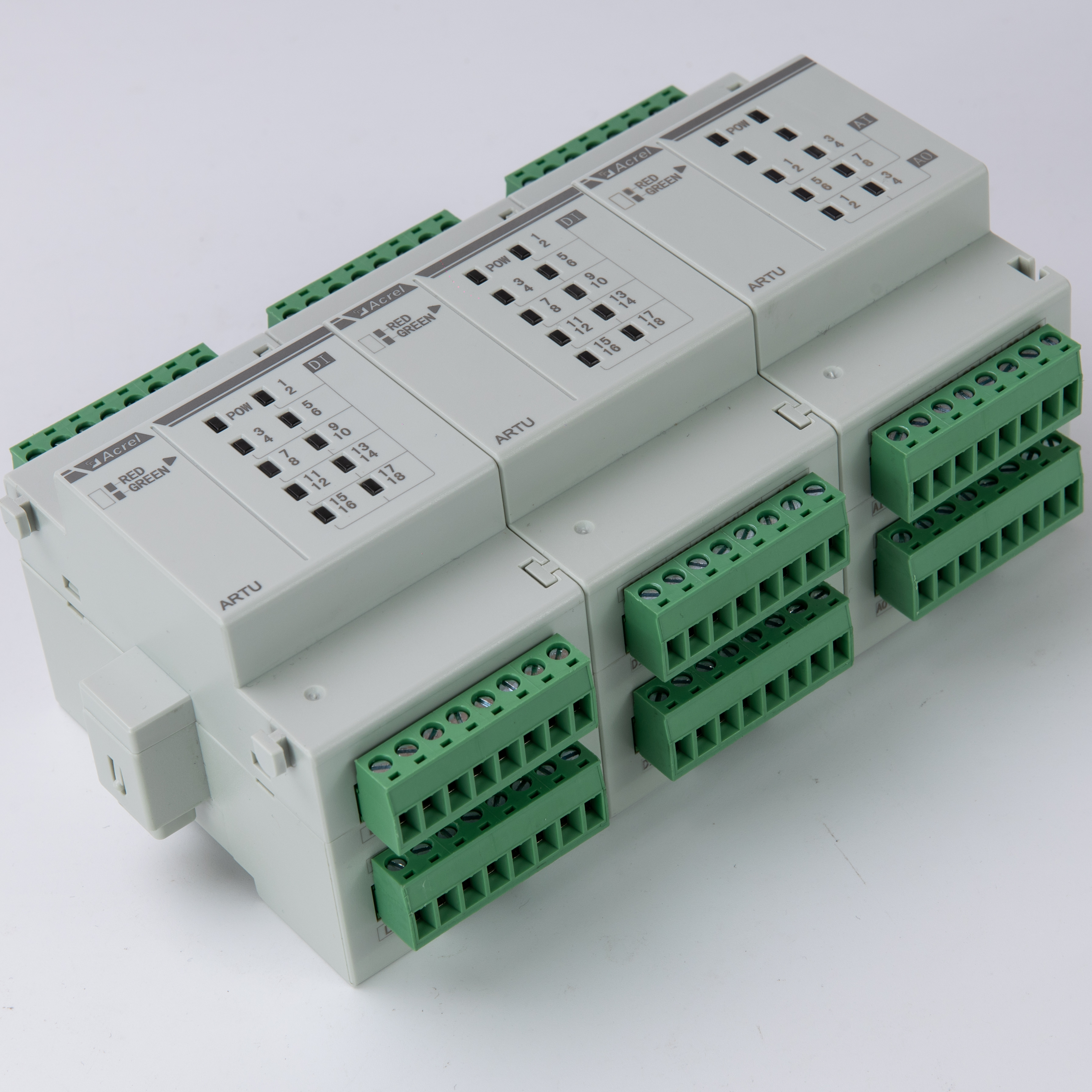

35mm DIN Rail Mounted

4 Modules 72mm Width

CE Certificated

For IoT Energy Management, Factory, School, Convenience Store

DC Dual-circuits Monitoring

Dual RS485 Communication

Rated Voltage 0~1000V DC

DO/DI Function

UL certified

High Accuracy Class 0.5

Built-in Bipolar Power Source for Hall Sensors

Smart Gateway

Data Tranfer Unit (DTU)

4G Communication

CE Certificated

Downstream RS485 Communication

Max. Access 25 Devices

Rated Current: 60A Direct Input

Bulit-in Relay

For Prepaid/Postpaid Billing System

Wireless WiFi/4G Communication Optional

RS485 Communication

Application:Shopping malls, Apartment, Dormitories and Retail Premises

Temperature Measure -50°C to 125°C

Current Measure 1-400A

High Accuracy Class 1

CT Powered

Backup Battery

Wireless Communication

Wireless Comm. LoRaWAN EU868MHz

Input Current 5A by CTs

868/915/923/470/433MHz LoRaWAN

35mm DIN Rail Mounted

4 Modules 72mm Width

CE Certificated

For IoT Energy Management, Factory, School

Rated Current: Up to 10000A

High Accuracy Class 0.5

Diameter 150mm

Split Core Open Type

Zero Power Consumption

No Open-circuit High-voltage Hazard

8-way client/server connection

RS485 Modbus-RTU

Support IPV4, IPV6

35mm din rail mounted

2-way 10-100mbits adaptive Ethernet communication

For Smart Power Distribution Automation

RS485 Modbus-RTU

2DI/2DO

12V power output

Multiple rate

LCD display

For Solar PV Energy Management System

AC Three Phase Measurement:U,I,kWh,kVar and etc

Bidirectional Metering

Input Current: 5A/1A by CTs

Communication:RS485,Modbus-RTU

Application:Inverter,Switchgear,Distribution Panel

6 Circuits 3 Phase Measurement

RJ12 Connection, Easy Installation

High Accuracy Class 0.5S

Work with SCADA System

CE Certificated

Application: Data Center

AC Three Phase Measurement

Input Current: 5A/1A by CTs

THD with 2-31st Harmonics

72*72mm

Ture RNS Measurement

4DI & 2DO

Pulse Output

7-inch Touch-Screen

Receive Max. 240 Sensors

Work with SCADA System

Founded in 2003, Acrel Co., Ltd.【Stock Code: 300286.SZ】 is a high-tech enterprise specializing in energy management solutions and electrical safety. Headquartered in Shanghai, Acrel offers innovative and sustainable solutions for microgrid energy efficiency and electrical safety. With over 600 patents and software copyrights, Acrel has deployed more than 28,000 system solutions globally, forming a comprehensive "cloud-edge-end" energy internet architecture.

Acrel Co., Ltd. is China

Digital Energy Meters Company and

Electricity Energy Meters Suppliers. Acrel's integrated product ecosystem spans from cloud platform software to end-user components, covering sectors such as power, renewable energy, data centers, smart buildings, transportation, and smart cities. These solutions enable intelligent, real-time energy management, enhancing energy security and reducing operational costs. We offer

Power Monitoring and Measurement Device for sale.

The company's production facility, Jiangsu Acrel Electric Manufacturing Co., Ltd., adheres to strict quality standards and environmental guidelines, with advanced testing centers and a commitment to lead-free production processes. Acrel's team of over 500 engineers delivers cutting-edge energy efficiency systems and smart energy solutions.

With a strong domestic presence, Acrel is actively expanding internationally, supported by a global network of sales and technical teams and an e-commerce platform that ensures seamless service experiences worldwide. Acrel is proud to help businesses improve efficiency, reduce consumption, and achieve sustainability goals.

Together, we are building a smarter, greener future.

Authorized Patents

0+Number of Customers Served

0+Total Employees

0+Manufacturing Base

0m²Welcome to connectIn the context of the rapid development of the new energy industry, scenarios such as commercial and industrial energy storage, battery swapping stations, and hou...

Read MoreIndustry Background and Application Importance Modern telecommunications networks have evolved into highly distributed, power-sensitive infrastructure systems. From core switching ...

Read MoreWith the rapid development of commercial real estate, power consumption management in shopping malls is gradually shifting from traditional manual operation to intelligent and data...

Read More1. Introduction With the continuous development of the global economy and industrial technology, electrical power systems play an increasingly important role in modern society. The...

Read MoreSignal Conditioning: The scaled-down analog signals from the sensors are passed through filters to remove noise and then fed into an Analog-to-Digital Converter (ADC).

Digital Conversion: The ADC converts the continuous analog signals (sine waves) into discrete digital values that a microprocessor can understand.

Computation: This is the core of the device. The microprocessor, following predefined algorithms, performs calculations on these digital values. The most basic calculation is active energy (kWh), which is the integral of power (voltage * current) over time. Modern meters also calculate:

Reactive Energy (kVARh): Crucial for understanding inefficient power use in inductive loads like motors.

Apparent Energy (kVAh): The vector sum of active and reactive power.

Power Factor (PF): The ratio of active power to apparent power, a key indicator of efficiency.

Harmonic Distortion: Measurement of unwanted frequencies on the electrical waveform caused by non-linear loads like computers and LED lights.

Real-time Power Quality Analysis: Monitoring voltage sags, swells, transients, and frequency variations that can damage sensitive equipment.

Load Profiling: Creating detailed charts of energy usage patterns over time to identify waste and opportunities for optimization.

Demand Monitoring: Tracking the maximum power (kW) used in a specific interval, which is a critical factor for commercial and industrial electricity bills.

Predictive Maintenance: By analyzing energy consumption patterns, these systems can detect anomalies that signal impending equipment failure, allowing for maintenance before a costly breakdown occurs.