Split Core

Clamp on Installation

High Accuracy Class 0.5

150-1000A Input Current

5A/1A Secondary Output

Application: Renovation Projects

Split Core

Clamp on Installation

High Accuracy Class 0.5

150-1000A Input Current

5A/1A Secondary Output

Application: Renovation Projects

Split Core

High Accuracy Class 0.5

Current Input 20-6000A

Current Output 5(1)A

Rectangular Hole Design

Measurement of current (I)

Application: Renovation Projects

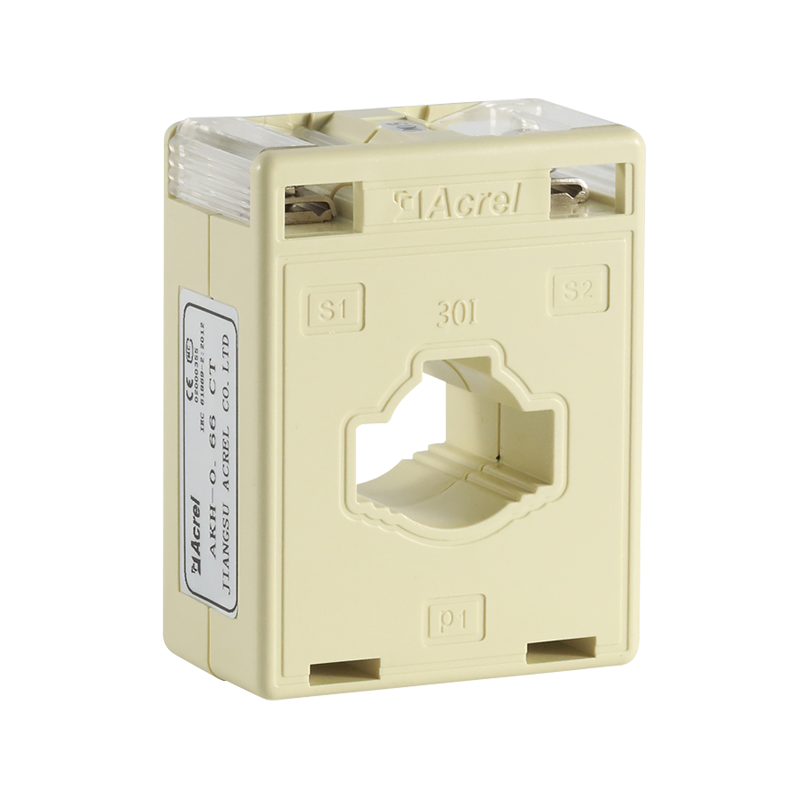

Solid Core

High Accuracy Class 0.5

5A output

Measurement of current (I)

Application: Busbar,Cables. New construction projects

Split Core Clamp on Installtion

High Accuracy Class 0.5

mA output

Measurement of current (I)

Application: Renovation Projects、Solar PV Projects

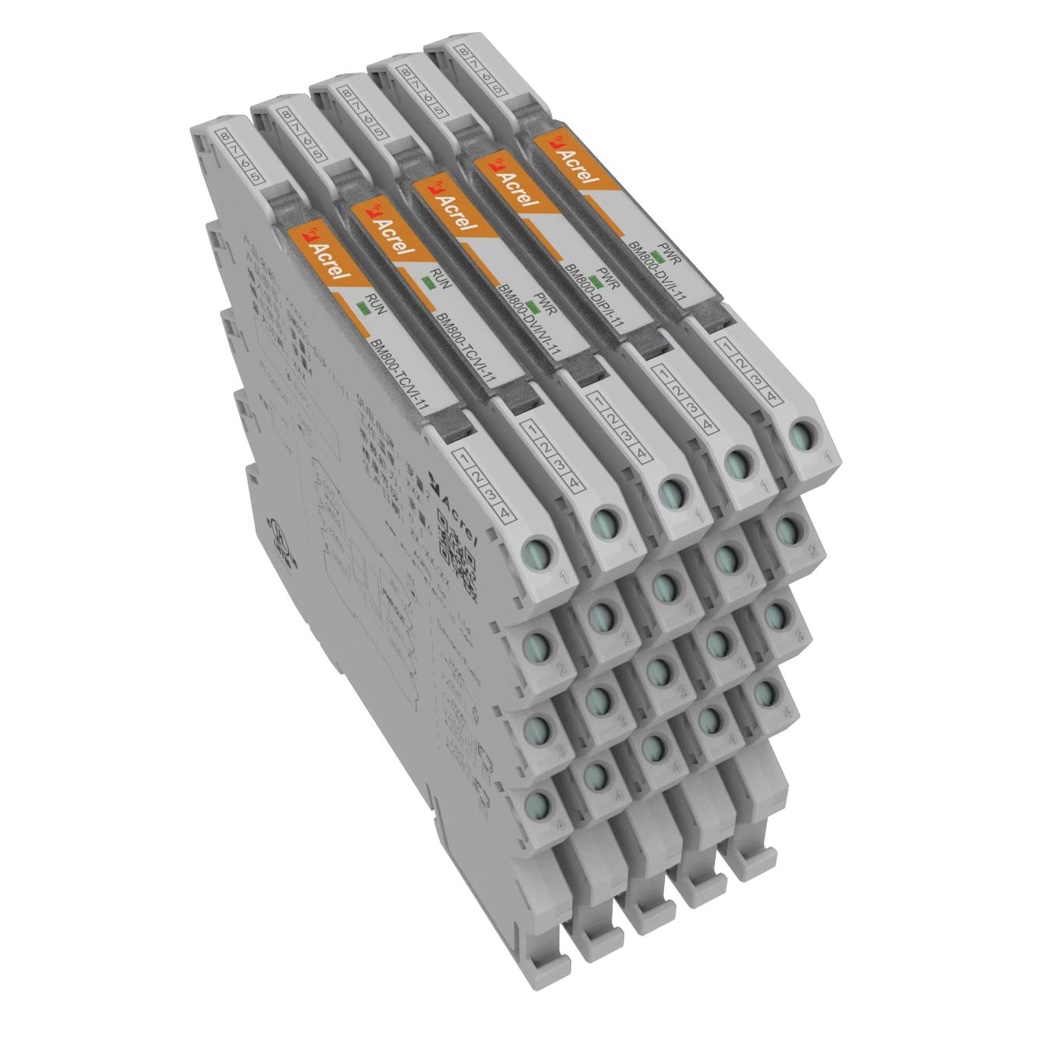

6.2mm Ultra-thin

DIP Switch for Input & Output Signal

CE & IEC Approval

Sofeware Configurable

Input Signal: 0~20mA,4~20mA, 0~5V,1~5V,0~10V,2~10V (Switchable)

Output Signal: 0~20mA,4~20mA, 0~5V,1~5V,0~10V,2~10V (Switchable)

UL Certification

High Accuracy Class 0.5

Split Core Open Type

Rated Current: 100-400A

mA/mV/A Outputs

Rated Voltage AC0.69kV

Rated Current: Up to 10000A

High Accuracy Class 0.5

Excellent Linearity

Split Core Open Type

Zero Power Consumption

No Open-circuit High-voltage Hazard

Rated Current: Up to 10000A

High Accuracy Class 0.5

Diameter 150mm

Split Core Open Type

Zero Power Consumption

No Open-circuit High-voltage Hazard

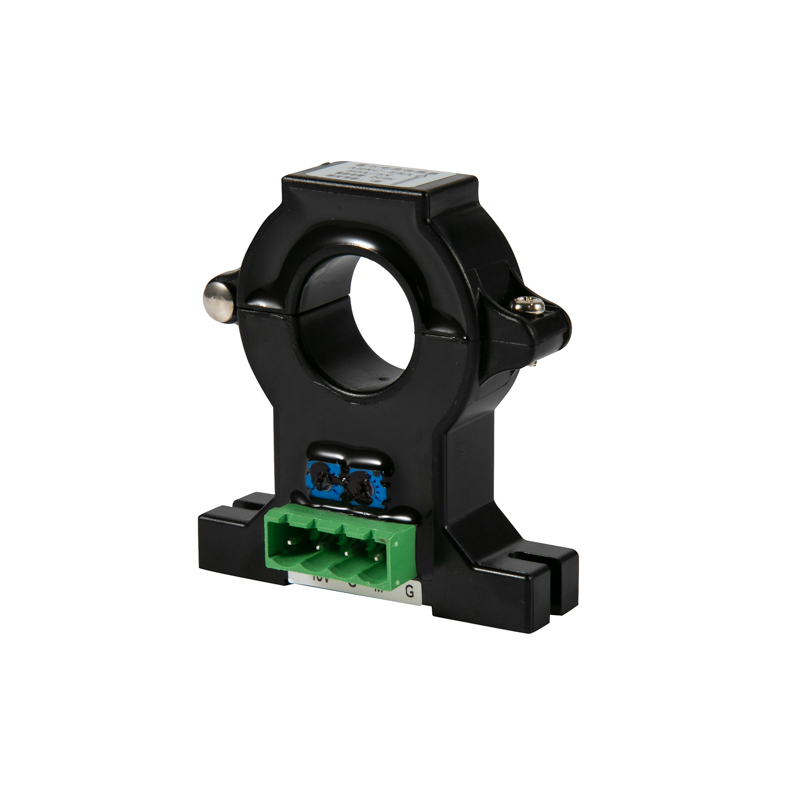

Input:DC0~500A

Ouput:DC 4~20mA

Power Supply:DC12V/24V

Application:Solar,Energy storage , Wind energy, UPS, BMS, EV charging pile

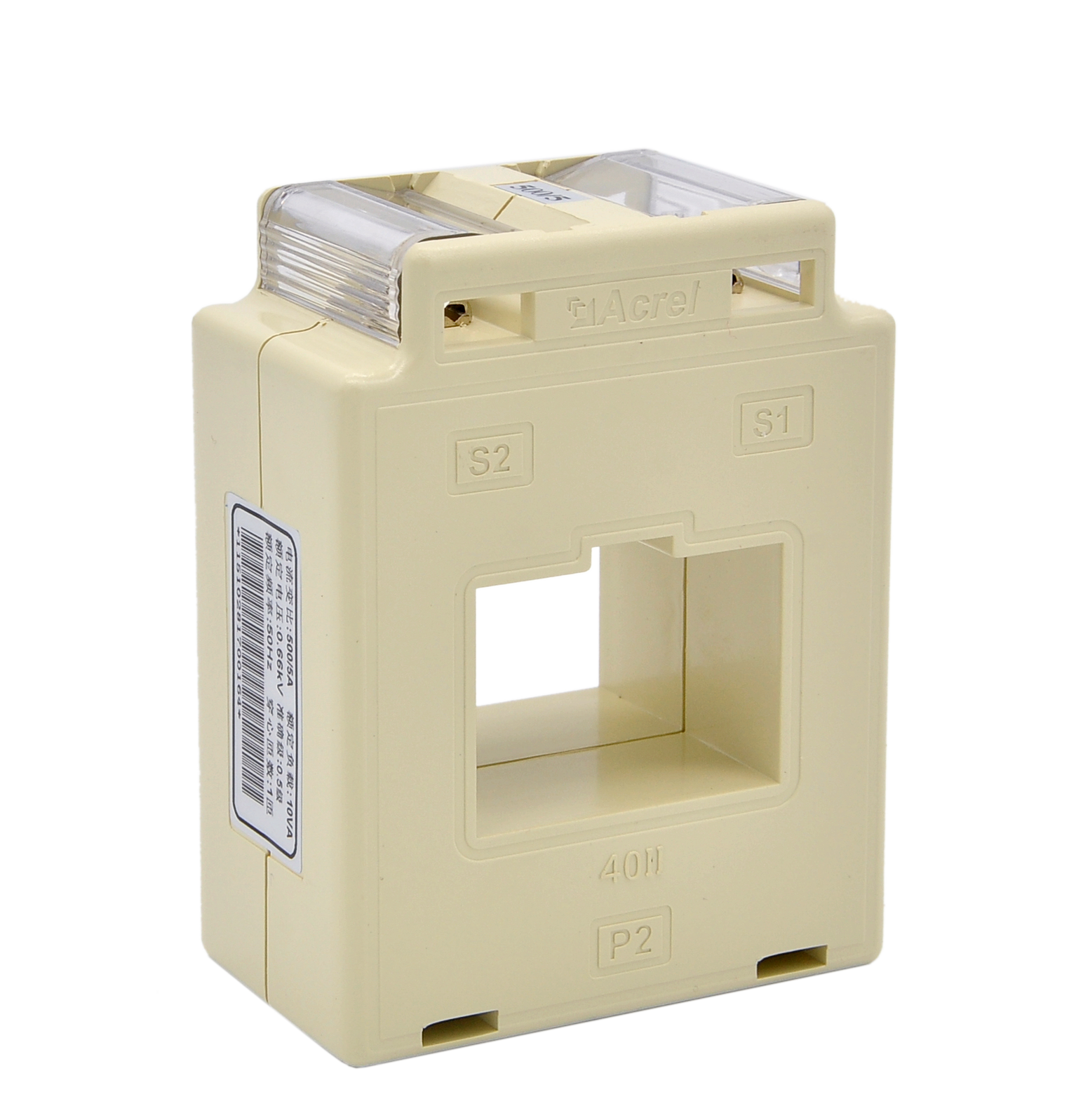

Solid Core

High Accuracy Class 0.5

IEC/EN61869-1;IEC/EN61869-2;CE

Horizontal square hole type

Application: Busbar,Cables. New construction projects

Solid Core

High Accuracy Class 0.5

IEC/EN61869-1;IEC/EN61869-2;CE

Vertical square hole type

Application: Busbar,Cables. New construction projects

Founded in 2003, Acrel Co., Ltd.【Stock Code: 300286.SZ】 is a high-tech enterprise specializing in energy management solutions and electrical safety. Headquartered in Shanghai, Acrel offers innovative and sustainable solutions for microgrid energy efficiency and electrical safety. With over 600 patents and software copyrights, Acrel has deployed more than 28,000 system solutions globally, forming a comprehensive "cloud-edge-end" energy internet architecture.

Acrel Co., Ltd. is China

Power Sensors Company and

Protection Current Transformer Suppliers. Acrel's integrated product ecosystem spans from cloud platform software to end-user components, covering sectors such as power, renewable energy, data centers, smart buildings, transportation, and smart cities. These solutions enable intelligent, real-time energy management, enhancing energy security and reducing operational costs. We offer

Protective Current Transformers for sale.

The company's production facility, Jiangsu Acrel Electric Manufacturing Co., Ltd., adheres to strict quality standards and environmental guidelines, with advanced testing centers and a commitment to lead-free production processes. Acrel's team of over 500 engineers delivers cutting-edge energy efficiency systems and smart energy solutions.

With a strong domestic presence, Acrel is actively expanding internationally, supported by a global network of sales and technical teams and an e-commerce platform that ensures seamless service experiences worldwide. Acrel is proud to help businesses improve efficiency, reduce consumption, and achieve sustainability goals.

Together, we are building a smarter, greener future.

Authorized Patents

0+Number of Customers Served

0+Total Employees

0+Manufacturing Base

0m²Welcome to connectIn the context of the rapid development of the new energy industry, scenarios such as commercial and industrial energy storage, battery swapping stations, and hou...

Read MoreIndustry Background and Application Importance Modern telecommunications networks have evolved into highly distributed, power-sensitive infrastructure systems. From core switching ...

Read MoreWith the rapid development of commercial real estate, power consumption management in shopping malls is gradually shifting from traditional manual operation to intelligent and data...

Read More1. Introduction With the continuous development of the global economy and industrial technology, electrical power systems play an increasingly important role in modern society. The...

Read MoreWith the increasing global emphasis on energy efficiency and sustainability, the use of power sensors in modern energy management systems has become increasingly important. Power sensors not only provide real-time energy consumption data, but also, through high-precision measurements, help businesses and households optimize energy use, improve system efficiency, and reduce operating costs. Power sensors are particularly indispensable in smart buildings, power systems, data centers, and other sectors.

Power sensors are electronic devices that can measure parameters such as voltage, current, and power in power systems in real time. By monitoring power, power sensors help users understand power usage and provide data support for further optimization measures. These sensors typically include current transformers, voltage sensors, and power analyzers, which accurately measure and record various key parameters in power systems.

Power sensors have a wide range of applications, from power systems and smart buildings to industrial production lines. They are often tightly integrated with energy management systems (EMS) to ensure efficient energy use by monitoring system performance in real time.

1. Real-Time Monitoring and Data Collection

One of the core functions of power sensors is real-time monitoring of power consumption. By accurately measuring current and voltage, power sensors can quickly respond to changes in the power system and collect data in real time. This data not only helps businesses and individuals understand energy usage but also provides a foundation for energy optimization and early warning.

For example, in smart buildings, power sensors can monitor power usage across the entire building in real time. If any specific area experiences abnormal power consumption, the system can immediately issue an alert, preventing energy waste or equipment failure.

2. Improving Energy Efficiency

By accurately measuring power, power sensors help users identify areas of energy waste within the system. For example, in industrial production lines, power sensors can help identify equipment that consumes excessive amounts of energy. Adjusting equipment operation or optimizing processes can improve overall energy efficiency.

3. Reducing Operating Costs

In high-energy-consuming locations such as data centers, power sensors can help managers accurately calculate energy consumption and adjust energy allocation based on real-time data. Optimizing energy usage not only improves system reliability but also significantly reduces operating costs.

As a high-tech company specializing in energy management solutions, Acrel Co., Ltd. has been committed to providing intelligent and sustainable energy management products and services since its establishment. We have accumulated extensive technical experience in power sensors and launched a series of integrated energy management products to help customers across various industries achieve efficient power monitoring and management.

Acrel’s power sensor solutions cover multiple industries, including smart cities, smart buildings, data centers, and renewable energy. We not only provide high-precision power measurement equipment, but also leverage cloud platforms and big data analytics to provide users with real-time, accurate energy management data and intelligent optimization recommendations.

With the continuous development of smart grid technology, power sensors are playing an increasingly important role in grid monitoring. One of the core goals of smart grids is to optimize the distribution and use of electricity through automation and information technology. Power sensors are part of the infrastructure that achieves this goal.

Power sensors enable smart grids to monitor power consumption in real time at every stage, including power generation, transmission, and distribution. Power sensors can help power companies detect potential problems in grid operations, enabling timely dispatch and adjustments, avoiding power waste and ensuring safe and stable grid operation.

1. Measurement Accuracy

Different application scenarios require different accuracy from power sensors. In industrial and commercial environments, high-precision sensors provide more accurate data, providing strong support for decision-making. Therefore, when selecting a power sensor, it is important to consider whether its measurement accuracy meets actual requirements.

2. Sensor Response Time

The response time of a power sensor directly impacts the real-time performance of the system. For applications requiring real-time monitoring, such as smart buildings and data centers, the faster the power sensor’s response time, the faster the system’s feedback, enabling more timely energy management decisions.

3. Sensor Compatibility and Scalability

With the continuous advancement of smart grids and energy management systems, sensor compatibility and scalability are becoming increasingly important. Selecting sensors that are compatible with multiple systems can reduce system construction and maintenance costs and increase flexibility for future system expansion.

Power sensors are playing an increasingly important role in energy management, and with the continuous advancement of technology, their application scenarios are expanding. For businesses and individuals, choosing high-quality power sensors can help improve energy efficiency, reduce operating costs, and promote sustainable development.

Leveraging its strong technical capabilities and extensive industry experience, Acrel Co., Ltd. will continue to innovate in power sensors and energy management, providing global customers with more intelligent and sustainable energy solutions, and working together to build a better green future.