Rated Current 80A Directly

MID Certificated

High Accuracy Class C

35mm DIN Rail Mounted

Pulse Output

4 Modules 72mm Width

For IoT Energy Management, Factory, School

Ethernet Communication

AC Three Phase Measurement

High Accuracy Class 0.2S

Panel Mounted Installation

4DI/2DO

2-63rd Harmonic

RS485 Communication

+86-18702106858 / +86-21-69156352

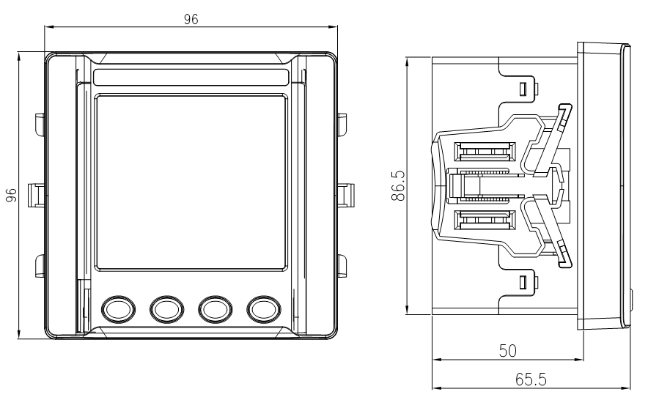

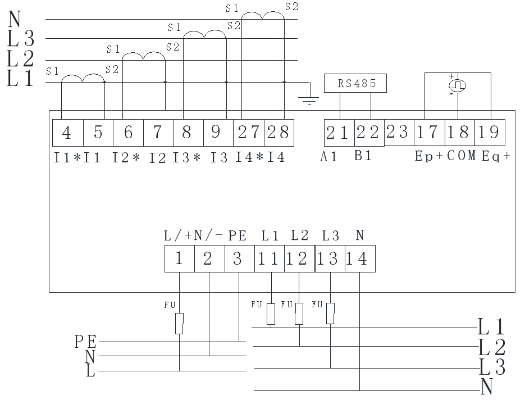

Acrel APM520 network power meter delivers exceptional precision and versatility for modern power grid monitoring. Featuring IEC 62053-22 0.2S class accuracy (with S option) in a compact 96×96mm panel design, it provides billing-grade energy measurement alongside comprehensive power quality analysis. The unit monitors harmonics through the 63rd order, interharmonics, and voltage flicker, while its integrated fault recorder automatically captures voltage sags, swells, interruptions, and inrush currents for advanced diagnostics.

Communication flexibility is a core strength, offering optional Ethernet Modbus-TCP, 4G, WiFi, LoRa, and NB-IoT modules in addition to standard RS485 and DL/T645-2007 protocols. The base configuration includes four digital inputs and two relay outputs, with expansion capabilities for analog outputs, temperature sensing, and leakage current monitoring. With IEC 61000 EMC compliance and robust event logging (128 alarm and switch records), the APM520 serves as a powerful, all-in-one solution for industrial and commercial energy management applications requiring high accuracy and extensive analytical capabilities.

| Display | Display method | Dot matrix liquid crystal; Switch between Chinese and English | ||

| Resolution | 128*128; | |||

| Backlight | White LED; | |||

| Visible area | 72 Shape: 38mm*46mm (1.78"/2.3"); | |||

| 96 Shape: 56mm*60mm (2.46"/3.2"); | ||||

| Signal | Electrical network | Three-phase three-wire, three-phase four-wire, see the wiring diagram; | ||

| Frequency | 45~65Hz; | |||

| Voltage | Rating: AC 3*57.7/100V, AC 3*63.5/110V, AC 3*230/400V, AC 3*400/690V (96 Shape only); | |||

| Overload: 1.2 times the rating (continuous); 2x rating/1 second; | ||||

| Power consumption: < 0.5VA(Every way); | ||||

| Current | Ratings: AC 3x 1 (1.2) A, AC 3x5(6)A; | |||

| Overload: 1.2 times the rating (continuous); 10x rating/1 second; | ||||

| Power consumption: < 0.5VA(Every way); | ||||

| Measurement accuracy | Voltage, current | IEC 61557-12 0.2% | ||

| Voltage harmonics, current harmonics | IEC 61557-12 1% | |||

| Frequency | IEC 61557-12 ±0.02Hz | |||

| Active power | IEC 61557-12 0.5% | |||

| Reactive power | IEC 61557-12 1% | |||

| Active electrical energy | 0.5S class GB/T 17215.321-2008 | |||

| C class GB/T 17215.321-2021 | ||||

| (0.2S accuracy when S is selected) | ||||

| 0.2S class GB/T 17215.321-2008 | ||||

| D class GB/T 17215.321-2021 | ||||

| Reactive power | IEC 62053-24 Class 1 | |||

| Power quality (only available when S is selected). | Waves recording | 20 waveforms, 10 waves before and after; | ||

| Waveform capture | 128 cycle points are stored per waveform; | |||

| Switch input | Dry contact input, built-in power supply; | |||

| Response time: less than 300ms | ||||

| Relay output | Contact type: normally open contact; | |||

| Contact capacity: AC 250V/3A DC 30V/3A; | ||||

| Energy pulse output | Output mode: photocoupler pulse with open collector; | |||

| Pulse constant: 10000imp/kWh (default); | ||||

| communication | RS485 interface/Modbus-RTU protocol and DLT645 protocol; | |||

| RJ45 interface (Ethernet)/Modbus-TCP protocol; | ||||

| Wireless interface | ||||

| power supply | Working range: AC 85V~265V; DC100V~350V | |||

| Power consumption: power consumption≤15VA; | ||||

| Safety | Power frequency withstand voltage | The power frequency withstand voltage between the housing and the auxiliary power supply, each input and output terminal group is AC 4kV/1min; | ||

| The power frequency withstand voltage between the auxiliary power supply and each input terminal and each output terminal group is AC 2kV/1min; | ||||

| The power frequency withstand voltage between the voltage input and other input and output terminal blocks is AC 2kV/1min; | ||||

| The power frequency withstand voltage between the current input and other input and output terminal blocks is AC 2kV/1min; | ||||

| The power frequency withstand voltage between the relay output and other input and output terminal blocks is AC 2kV/1min; | ||||

| The power frequency withstand voltage between the terminal groups of switching input, communication, analog output and pulse output is AC 1kV/1min; | ||||

| Insulation resistance | Inputs、outputs to the shell>100MΩ; | |||

| Electromagnetic compatibility | Complies with IEC 61000 standard (Level 4); | |||

| Environment | Operating temperature:-25℃~+70℃;Storage temperature:-40℃~+85℃; | |||

| Relative humidity:≤95% without condensation;Altitude:≤2500m; | ||||

| Protection Level | Display panel IP54; (Optionally IP65). | |||

| Standards | IEC 60068-2-1 | Environmental Testing-Part 2-1:Tests Test A:Cold IDA | ||

| IEC 60068-2-2 | Environmental Testing Part 2-2:Tests Test B:Dry heat | |||

| IEC 60068-2-30 | Environmental Testing Part 2-30:Tests Test Db:Damp heat,cyclic (12+12h) | |||

| IEC 61000-4 | Electromagnetic compatibility-Testing and measurement techniques | |||

| IEC 61557-12 | Electrical safety in low voltage distribution systems up to 1 000V a.c. and 1 500V d.c –Equipment for testing, measuring or monitoring of protective measures — Part12:Performances measuring and monitoring devices(PMD) | |||

| IEC 62053-22 | Electricity metering equipment (a.c.)-Particular requirements - Part22:Static meter for active energy(class 0.2S and 0.5S) | |||

| IEC 62053-24 | Electricity metering equipment (a.c.)-Particular requirements - Part24:Static meter for reactive energy at fundamental frequency (classes 0.5S 1S and 1) | |||

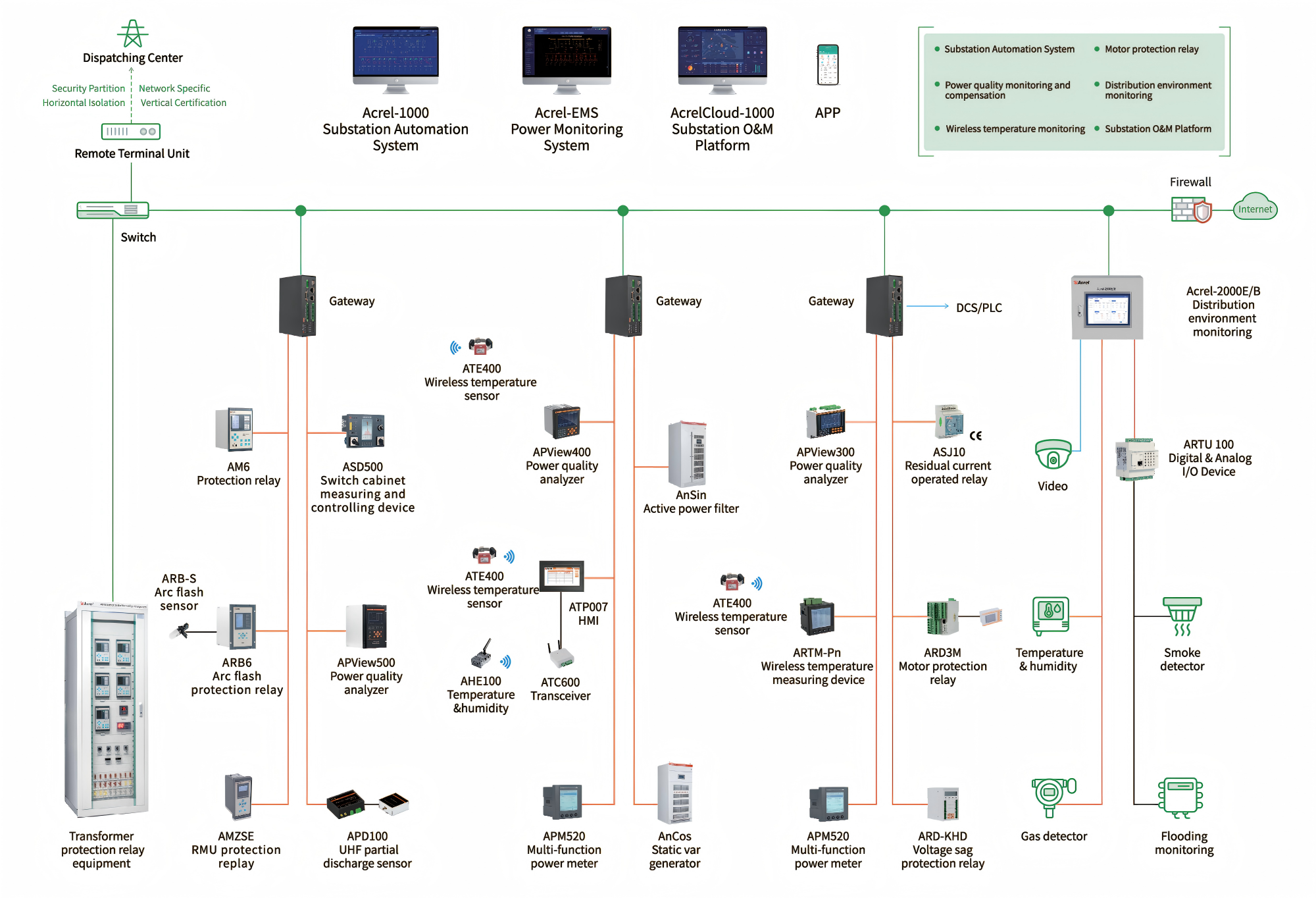

Power Monitoring Solution

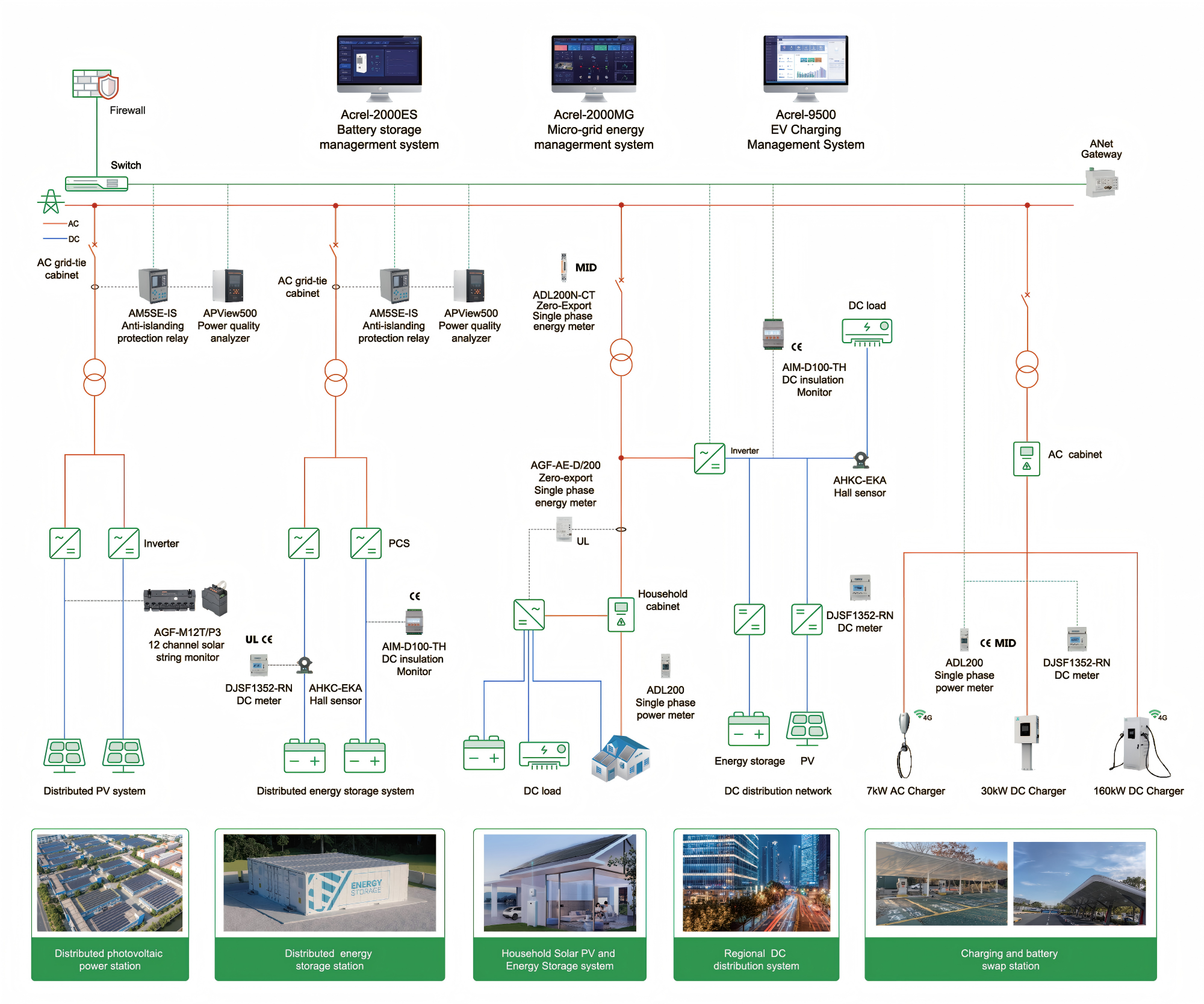

Renewable Energy

Founded in 2003, Acrel Co., Ltd.【Stock Code: 300286.SZ】 is a high-tech enterprise specializing in energy management solutions and electrical safety. Headquartered in Shanghai, Acrel offers innovative and sustainable solutions for microgrid energy efficiency and electrical safety. With over 600 patents and software copyrights, Acrel has deployed more than 28,000 system solutions globally, forming a comprehensive "cloud-edge-end" energy internet architecture.

Acrel Co., Ltd. is China Wholesale Ethernet Communication High Accuracy Class 0.2S Panel Mounted Energy Meter Manufacturers and Ethernet Communication High Accuracy Class 0.2S Panel Mounted Energy Meter Factory. Acrel's integrated product ecosystem spans from cloud platform software to end-user components, covering sectors such as power, renewable energy, data centers, smart buildings, transportation, and smart cities. These solutions enable intelligent, real-time energy management, enhancing energy security and reducing operational costs. We offer Ethernet Communication High Accuracy Class 0.2S Panel Mounted Energy Meter for sale.

The company's production facility, Jiangsu Acrel Electric Manufacturing Co., Ltd., adheres to strict quality standards and environmental guidelines, with advanced testing centers and a commitment to lead-free production processes. Acrel's team of over 500 engineers delivers cutting-edge energy efficiency systems and smart energy solutions.

With a strong domestic presence, Acrel is actively expanding internationally, supported by a global network of sales and technical teams and an e-commerce platform that ensures seamless service experiences worldwide. Acrel is proud to help businesses improve efficiency, reduce consumption, and achieve sustainability goals.

Together, we are building a smarter, greener future.

Authorized Patents

0+Number of Customers Served

0+Total Employees

0+Manufacturing Base

0m²Welcome to connectIn the context of the rapid development of the new energy industry, scenarios such as commercial and industrial energy storage, battery swapping stations, and household photovoltaic-storage systems have placed higher demands on the accuracy, compatibility, and intelligence of elect...

Read MoreIndustry Background and Application Importance Modern telecommunications networks have evolved into highly distributed, power-sensitive infrastructure systems. From core switching facilities and data centers to remote radio units, base stations, edge nodes, and customer premises equipment, telecom s...

Read MoreWith the rapid development of commercial real estate, power consumption management in shopping malls is gradually shifting from traditional manual operation to intelligent and data-driven management. In large shopping centers, the large number of tenants, diverse electricity usage patterns, high ene...

Read More