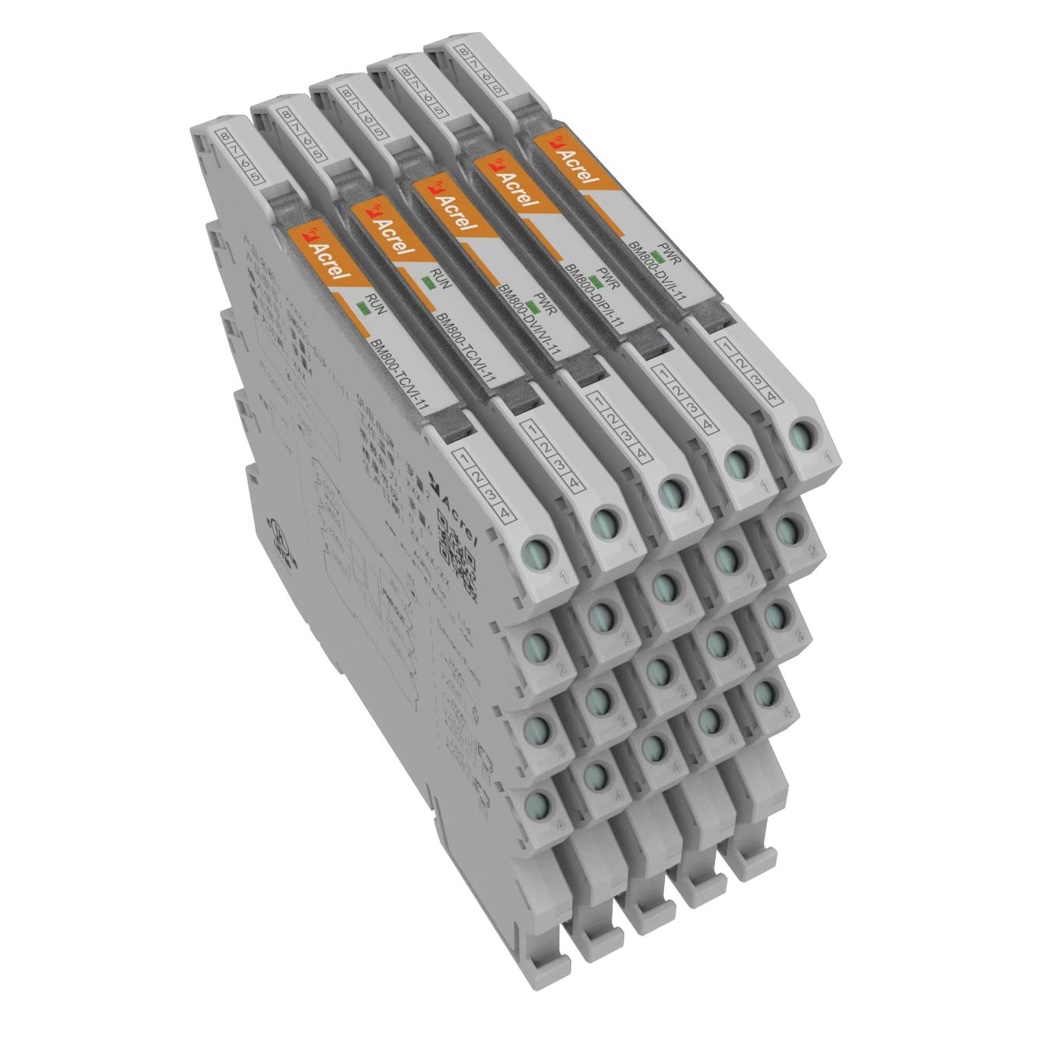

6.2mm Ultra-thin

DIP Switch for Input & Output Signal

CE & IEC Approval

Sofeware Configurable

Input Signal: 0~20mA,4~20mA, 0~5V,1~5V,0~10V,2~10V (Switchable)

Output Signal: 0~20mA,4~20mA, 0~5V,1~5V,0~10V,2~10V (Switchable)

6.2mm Ultra-thin

DIP Switch for Input & Output Signal

CE & IEC Approval

Sofeware Configurable

Input Signal: 0~20mA,4~20mA, 0~5V,1~5V,0~10V,2~10V (Switchable)

Output Signal: 0~20mA,4~20mA, 0~5V,1~5V,0~10V,2~10V (Switchable)

Founded in 2003, Acrel Co., Ltd.【Stock Code: 300286.SZ】 is a high-tech enterprise specializing in energy management solutions and electrical safety. Headquartered in Shanghai, Acrel offers innovative and sustainable solutions for microgrid energy efficiency and electrical safety. With over 600 patents and software copyrights, Acrel has deployed more than 28,000 system solutions globally, forming a comprehensive "cloud-edge-end" energy internet architecture.

Acrel Co., Ltd. is China

Wholesale Smart Signal Conditioners Manufacturers and

Signal Conditioning Devices Factory. Acrel's integrated product ecosystem spans from cloud platform software to end-user components, covering sectors such as power, renewable energy, data centers, smart buildings, transportation, and smart cities. These solutions enable intelligent, real-time energy management, enhancing energy security and reducing operational costs. We offer

Wholesale Signal Conditioning Modules for sale.

The company's production facility, Jiangsu Acrel Electric Manufacturing Co., Ltd., adheres to strict quality standards and environmental guidelines, with advanced testing centers and a commitment to lead-free production processes. Acrel's team of over 500 engineers delivers cutting-edge energy efficiency systems and smart energy solutions.

With a strong domestic presence, Acrel is actively expanding internationally, supported by a global network of sales and technical teams and an e-commerce platform that ensures seamless service experiences worldwide. Acrel is proud to help businesses improve efficiency, reduce consumption, and achieve sustainability goals.

Together, we are building a smarter, greener future.

Authorized Patents

0+Number of Customers Served

0+Total Employees

0+Manufacturing Base

0m²Welcome to connectIn the context of the rapid development of the new energy industry, scenarios such as commercial and industrial energy storage, battery swapping stations, and hou...

Read MoreIndustry Background and Application Importance Modern telecommunications networks have evolved into highly distributed, power-sensitive infrastructure systems. From core switching ...

Read MoreWith the rapid development of commercial real estate, power consumption management in shopping malls is gradually shifting from traditional manual operation to intelligent and data...

Read More1. Introduction With the continuous development of the global economy and industrial technology, electrical power systems play an increasingly important role in modern society. The...

Read MoreIn the field of industrial automation, smart switch signal conditioners have always been an indispensable "bridge" connecting field sensors to control systems. However, their role is undergoing a revolutionary evolution from a simple analog signal converter to an intelligent, networked critical data node. This evolution is the cornerstone for achieving efficient Condition Monitoring (CM) and Predictive Maintenance (PdM). As a high-tech enterprise with years of deep experience in energy efficiency management and electrical safety, the practice of Acrel Co., Ltd. clearly demonstrates how this technological evolution creates core value for customers.

Traditional analog signal conditioners had singular functions, primarily performing three tasks: isolation (protecting the control system from high voltage and surges on the field side), conversion (converting weak signals from sensors like thermocouples, RTDs, and strain gauges into standard 4-20mA or 0-10V signals), and filtering (eliminating some noise). At this stage, its role was that of a passive, "dumb" translator, only ensuring the signal could be transmitted accurately, but the deep information contained within the signal itself (such as sensor health, environmental interference, line integrity) was completely ignored. System operation and maintenance could only make judgments based on the received final data, unable to distinguish between a process abnormality or a failure in the measurement chain components themselves. The maintenance model was mostly reactive or periodic, which was costly and inefficient.

The intelligent signal conditioning solutions provided by Acrel go beyond traditional signal conversion, upgrading it to a "data doctor" deployed at the device edge. This evolution is mainly reflected in the following three aspects, perfectly aligning with its "Cloud-Edge-End" energy internet architecture:

Self-diagnosis and Sensing Capability: Intelligent signal conditioners possess powerful self-diagnostic functions. They can monitor the status of the sensor loop in real-time, such as open circuits, short circuits, wiring errors, power abnormalities, etc., and immediately report alarm information through digital communication. This is equivalent to equipping the measurement link itself with a 7x24-hour "stethoscope," discovering potential failures before the sensor fails, avoiding production accidents or energy consumption deviations caused by measurement inaccuracies.

Advanced Signal Processing and Data Optimization: At the "edge," the intelligent signal conditioner, equipped with a high-performance processor, can process raw signals for ambient temperature compensation, linearization correction, advanced filtering, etc. For example, in scenarios involving microgrids and smart power distribution, which Acrel covers, monitoring the temperature of electrical connection points is crucial. The intelligent conditioner can directly process the non-linear signals of thermocouples, provide high-precision temperature values with cold junction compensation, and upload clean, reliable data to the system, laying the foundation for accurate condition analysis.

Digital Interconnection and Predictive Insight: This is the core of intelligence. By supporting industrial protocols such as Modbus, PROFINET, EtherNet/IP, the intelligent signal conditioner is no longer an isolated point but an addressable intelligent node in the Acrel energy management cloud platform network. It not only transmits process variables (like temperature, pressure, flow) but also device status information (like health status, operating hours, ambient temperature). This allows maintenance personnel to monitor the health status of thousands of measurement points in real-time on Acrel's energy efficiency management platform (such as the AcrelEMS Enterprise Microgrid Energy Efficiency Management Platform), rather than just monitoring process parameters.

Acrel's core expertise lies in energy management and electrical safety, and its intelligent signal conditioning solutions are closely centered around this.

In Electrical Connection Point Temperature Monitoring: By equipping or connecting ATE series wireless temperature sensors with intelligent conditioning units, the Acrel system can continuously monitor the temperature of key connection points in switchgear, transformers, and distribution boxes. The intelligent conditioner is responsible for processing the sensor's weak signals, overcoming strong electromagnetic interference, and uploading accurate temperature data along with sensor battery level information. The system uses this trend data to provide early warnings of overheating risks caused by poor contact, overload, etc., achieving predictive maintenance and effectively preventing fire hazards.

In Microgrid and Power Quality Analysis: The requirements for conditioning current and voltage signals are extremely high. Acrel's intelligent solutions ensure that the most raw, high-fidelity power data is provided to the energy analysis platform for analyzing harmonics, power factor, unbalance, etc. Long-term trend analysis of this data can predict issues like equipment insulation aging and capacitor life decay, thereby planning maintenance windows and ensuring the efficient and stable operation of the microgrid system.

The evolution from analog to intelligent marks the transformation of the signal conditioner from a simple interface device to an intelligent edge device providing critical decision-making data. For Acrel, this is highly synergistic with its strategic "Cloud-Edge-End" architecture, making its energy efficiency management and electrical safety solutions more proactive, intelligent, and reliable. By integrating intelligent signal conditioners into its comprehensive product ecosystem, Acrel empowers customers not just to "manage energy," but to "deeply understand the health status of the energy system," ultimately achieving comprehensive value in reducing operational costs, improving energy security, and meeting sustainable development goals.

In modern energy management and electrical safety systems, data accuracy, reliability, and real-time performance are the foundation of all intelligent decision-making. The key to ensuring this high-quality data is accurately transmitted from field sensors to upper-level systems is Signal Conditioning technology. It acts as an indispensable "translator" and "guardian," building a robust and efficient bridge between the physical world and digital systems.

As a high-tech enterprise deeply engaged in the energy internet sector, Acrel Co., Ltd. has deployed over 28,000 system solutions globally since its establishment in 2003, all relying on profound understanding and sophisticated application of signal conditioning technology.

1. Signal Amplification and Standardization: Many sensors (such as current transformers or RTD temperature sensors) output very weak raw signals (millivolt level) that are highly susceptible to being drowned out by noise during transmission. The primary task of signal conditioning circuits is to precisely amplify these weak signals and convert them into standardized signal ranges (e.g., 4-20mA, 0-5V, or 0-10V) so they can be accurately identified and processed by Acrel's various data acquisition units, power monitoring instruments, and intelligent gateways.

2. Noise Filtering and Anti-interference: Industrial and power environments are filled with electromagnetic interference (EMI), which can severely distort measurement signals. Acrel's equipment incorporates high-performance filtering circuits that effectively filter out this high-frequency noise, ensuring that data such as current, voltage, and power factor collected in complex electrical environments (like data centers, smart factories, and substations) remains pure and accurate, providing reliable basis for energy efficiency analysis and electrical safety diagnosis.

3. Electrical Isolation Protection: This is an aspect Acrel particularly emphasizes in the field of electrical safety. High-voltage surges may occur on site due to lightning strikes, equipment failures, or other accidents. Signal conditioning modules use technologies like optocouplers or magnetic isolation to establish an electrical isolation barrier between the sensor side and the system side. This not only prevents dangerous high voltages from damaging backend expensive Acrel cloud platform servers, edge computing gateways, or monitoring systems, protecting both equipment and personnel, but also completely eliminates measurement errors caused by ground loops, ensuring data authenticity.

4. Linearization and Compensation: Some sensors' outputs don't have a perfect linear relationship with the measured parameters (e.g., thermocouples). Acrel's intelligent devices use built-in algorithms and signal conditioning circuits to perform linearization processing and temperature compensation on these signals, correcting distortions and ensuring the final digital reading accurately reflects the physical parameter being measured.

For Acrel, excellent signal conditioning technology is the fundamental pillar supporting its comprehensive energy internet architecture from "cloud" to "edge" to "end." It ensures that every piece of energy data collected from thousands of field sensors is true and reliable. This enables Acrel's energy efficiency management platform to perform precise energy consumption analysis, early warning, and optimization, ultimately helping global customers enhance energy security, reduce operational costs, and achieve sustainability goals. It is this invisible "data bridge" that silently supports Acrel's mission to "build a smarter, greener future."

As a high-tech enterprise specializing in energy management and electrical safety, Acrel Co., Ltd. has been committed to providing innovative and sustainable solutions for global customers since its founding in 2003. With over 600 patents and software copyrights and more than 28,000 system solutions deployed worldwide, Acrel deeply understands that obtaining accurate, reliable, and stable raw data from the sensor side in complex industrial field environments is the cornerstone of all intelligent management and analysis. This crucial first step is accomplished by Signal Conditioning Modules.

Acrel's signal conditioning modules, acting as key "edge" and "end" components within its "cloud-edge-end" energy internet architecture, serve as the "translator" and "guardian" between sensors and upper-level systems (such as PLCs, SCADA systems, or the Acrel cloud platform). Their core functions for achieving precise conversion are mainly reflected in the following aspects:

Many sensors (such as shunts for current measurement and strain gauges for pressure detection) output very weak raw signals at the millivolt (mV) level. Such signals are extremely easily drowned out by environmental noise during long-distance transmission. Acrel's signal conditioning modules integrate high-precision, low-noise operational amplifiers that can amplify these weak signals losslessly to standardized levels more suitable for acquisition and transmission (such as 0-5V, 0-10V, or 4-20mA), significantly improving signal resolution and measurement signal-to-noise ratio, and ensuring data validity.

Industrial sites are filled with electromagnetic interference (EMI) from motors, frequency converters, wireless devices, etc. This noise superimposes itself on the useful sensor signal, causing measurement distortion. Leveraging its profound experience in the field of electrical safety, Acrel integrates efficient hardware filtering circuits (such as low-pass filters) into its modules, which can specifically filter out high-frequency noise of specific frequencies, allowing only effective DC or low-frequency signals to pass. This provides a pure data source for subsequent precise metering and energy analysis.

This is an aspect that Acrel, as an electrical safety expert, particularly emphasizes. The field sensor side may accidentally introduce high-voltage transient pulses or have ground potential differences. If left unaddressed, this can damage expensive backend equipment and even endanger personnel safety. Acrel's signal conditioning modules use optical isolation or magnetic isolation technology to establish reliable electrical isolation barriers between input, output, and power supply. This means that even if a high-voltage fault occurs on the sensor side, it can be effectively contained within the module and will not conduct to the control system side, thereby protecting the entire system's safety while completely eliminating measurement errors caused by ground loops.

The output of many sensors is not a perfect linear relationship with the measured quantity. For example, the temperature-voltage curve of a thermocouple is nonlinear, and the resistance-temperature relationship of a Pt100 RTD also exhibits a certain curve. Acrel's modules use built-in Application-Specific Integrated Circuits (ASICs) or high-performance microprocessors to run precise algorithms to linearize these nonlinear signals, outputting a smooth, standardized straight line. Furthermore, they can perform Cold Junction Compensation (CJC) - automatically compensating for temperature fluctuations at the thermocouple reference junction (cold end) - ensuring the final display always shows the true temperature at the measurement end.

Acrel's ecosystem needs to connect to a wide variety of sensors. Its signal conditioning modules can perform high-precision conversion between different signal types, for example:

Resistance to Standard Signal: Converting changes in RTDs like Pt100 into 4-20mA signals.

AC Signal to DC Signal: Converting the AC signal output by Current Transformers (CTs) into a DC voltage/current signal proportional to the AC RMS value, used for accurate energy consumption metering.

In summary, Acrel's signal conditioning modules are far more than simple interface converters. They incorporate the company's core technologies in hardware design, electrical safety, signal processing, and energy metering. Through this series of precise signal processing steps - amplification, filtering, isolation, linearization, and conversion - they transform raw, vulnerable, non-standard signals from field sensors into stable, pure, and standardized data. This provides a solid and reliable data foundation for Acrel's energy management cloud platform and intelligent solutions, ultimately helping customers achieve their goals of improving efficiency, reducing consumption, and sustainable development.