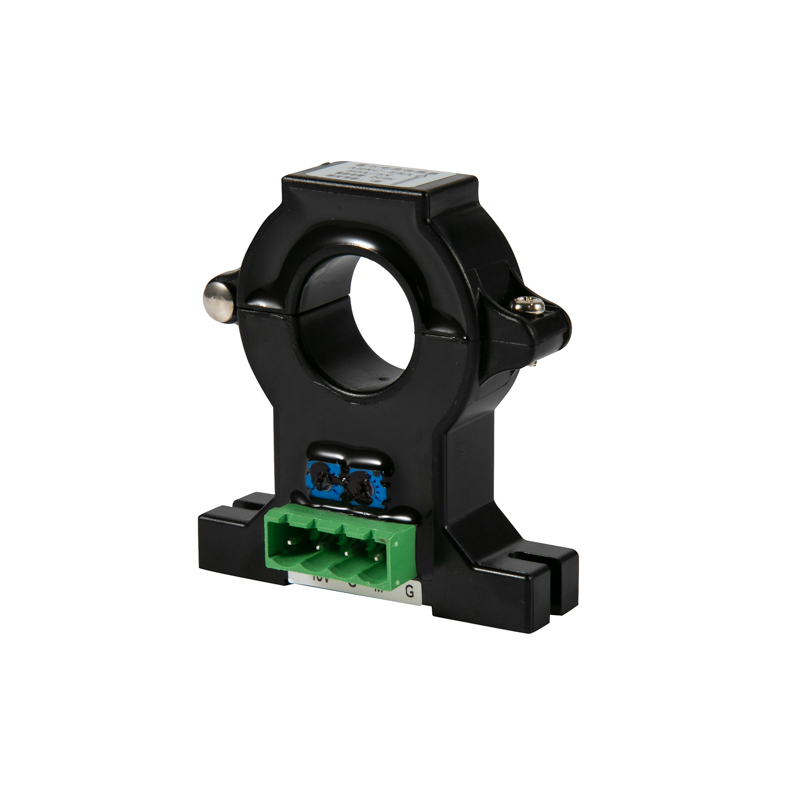

Input:DC0~500A

Ouput:DC 4~20mA

Power Supply:DC12V/24V

Application:Solar,Energy storage , Wind energy, UPS, BMS, EV charging pile

Input:DC0~500A

Ouput:DC 4~20mA

Power Supply:DC12V/24V

Application:Solar,Energy storage , Wind energy, UPS, BMS, EV charging pile

Founded in 2003, Acrel Co., Ltd.【Stock Code: 300286.SZ】 is a high-tech enterprise specializing in energy management solutions and electrical safety. Headquartered in Shanghai, Acrel offers innovative and sustainable solutions for microgrid energy efficiency and electrical safety. With over 600 patents and software copyrights, Acrel has deployed more than 28,000 system solutions globally, forming a comprehensive "cloud-edge-end" energy internet architecture.

Acrel Co., Ltd. is China

Wholesale AC/DC Hall Current Sensors Manufacturers and

Hall Effect Current Sensors Factory. Acrel's integrated product ecosystem spans from cloud platform software to end-user components, covering sectors such as power, renewable energy, data centers, smart buildings, transportation, and smart cities. These solutions enable intelligent, real-time energy management, enhancing energy security and reducing operational costs. We offer

Wholesale Hall-Effect Current Sensor for sale.

The company's production facility, Jiangsu Acrel Electric Manufacturing Co., Ltd., adheres to strict quality standards and environmental guidelines, with advanced testing centers and a commitment to lead-free production processes. Acrel's team of over 500 engineers delivers cutting-edge energy efficiency systems and smart energy solutions.

With a strong domestic presence, Acrel is actively expanding internationally, supported by a global network of sales and technical teams and an e-commerce platform that ensures seamless service experiences worldwide. Acrel is proud to help businesses improve efficiency, reduce consumption, and achieve sustainability goals.

Together, we are building a smarter, greener future.

Authorized Patents

0+Number of Customers Served

0+Total Employees

0+Manufacturing Base

0m²Welcome to connectIn the context of the rapid development of the new energy industry, scenarios such as commercial and industrial energy storage, battery swapping stations, and hou...

Read MoreIndustry Background and Application Importance Modern telecommunications networks have evolved into highly distributed, power-sensitive infrastructure systems. From core switching ...

Read MoreWith the rapid development of commercial real estate, power consumption management in shopping malls is gradually shifting from traditional manual operation to intelligent and data...

Read More1. Introduction With the continuous development of the global economy and industrial technology, electrical power systems play an increasingly important role in modern society. The...

Read MoreIn the fields of energy management and electrical safety, high-precision, highly reliable, and isolated current detection is the cornerstone of achieving system intelligence. The Hall Effect Current Sensor, an ancient physical phenomenon, is the core of modern AC/DC current sensing technology. As a leader in this field, Acrel Co., Ltd. deeply understands and masters this principle, transforming it into a key technology that ensures the safe and efficient operation of countless systems.

The basic principle of the Hall Effect Current Sensor is: when an electric current flows through a conductor or semiconductor sheet placed in a magnetic field, if the direction of the magnetic field is perpendicular to the direction of the current, a stable potential difference, namely the Hall voltage, is generated in a direction perpendicular to both the current and the magnetic field. This voltage signal is proportional to the magnetic flux density (and thus to the measured current that generates this magnetic field).

1. Non-Contact Measurement – The Cornerstone of Safety and Reliability: Hall current sensors use a non-contact measurement method. The sensor itself is electrically isolated from the measured high-voltage, high-current circuit through high-performance insulating materials. This aligns perfectly with Acrel's mission to provide electrical safety solutions. This isolation effectively prevents high-voltage side faults from impacting the low-voltage measurement circuit, greatly ensuring the safety of personnel and equipment, while also eliminating the power consumption and heat generation issues associated with traditional shunt measurement.

2. AC/DC Compatibility – A Broad Application Vision: Sensors based on the Hall Effect Current Sensor have a key advantage: they can respond to both static (DC) and changing (AC) magnetic fields. This means it can measure not only alternating current (AC) but also direct current (DC), which is impossible for traditional electromagnetic induction current transformers (CTs). Leveraging this technology, Acrel seamlessly integrates its sensor product lines into complex scenarios requiring hybrid AC/DC measurement, such as photovoltaic power generation systems (DC-side components and AC grid connection), electric vehicle charging facilities, data center UPS power supplies, and variable frequency drive systems, perfectly supporting its "cloud-edge-end" energy Internet architecture that covers industries like power, renewable energy, and transportation.

3. From Physical Phenomenon to Industrial Product – Acrel's Engineering Wisdom: Converting the weak Hall voltage signal into a standard, stable, and high-precision industrial signal output requires advanced signal conditioning (amplification, filtering), temperature compensation, and calibration technologies. Relying on its profound technical accumulation of over 600 patents and software copyrights, and its manufacturing base (Jiangsu Acrel Electric Manufacturing Co., Ltd.) that strictly adheres to quality standards, Acrel ensures that each sensor boasts excellent accuracy, low-temperature drift, and long-term stability. Its advanced testing center and lead-free production process are the strongest backing for product quality.

4. Enabling Intelligent Management – The Starting Point of Data: The standardized analog or digital signals output by Hall current sensors are the most front-end and fundamental data source for energy management systems. These real-time, accurate current data points are collected and uploaded to Acrel's cloud platform and edge computing devices. After analysis and processing, they ultimately present users with a complete picture of power generation, consumption, and distribution, serving as the original driver for achieving intelligent real-time energy management, enhancing energy security, and reducing operational costs.

In summary, the Hall Effect Current Sensor provides a solid physical foundation for AC/DC current detection, and Acrel, through continuous technological innovation and exquisite engineering manufacturing, transforms this principle into a series of high-performance, highly reliable industrial products. As critical "nerve endings" in its integrated solutions, these products collectively provide precise data power for the continuous realization of the vision of "building a smarter, greener future."

In modern energy management and electrical safety systems, accurate and isolated current measurement serves as the fundamental building block for achieving intelligent system operation. This represents the core value proposition of Hall effect current sensors. The underlying principle revolves around a physical phenomenon known as the "Hall Effect" - when an electrical current passes through a conductor or semiconductor material situated within a magnetic field, a measurable voltage potential, known as the Hall voltage, develops across the material in the direction perpendicular to both the current flow and magnetic field orientation.

This sophisticated non-contact measurement methodology delivers transformative benefits: it establishes complete electrical isolation between the primary power circuit and secondary measurement circuitry, thereby ensuring fundamental protection for both equipment and personnel. Additionally, this approach introduces negligible additional power loss to the measured circuit while demonstrating exceptional capability in accurately measuring DC, AC, and even complex irregular current waveforms, making it particularly indispensable in high-current industrial applications.

Since its establishment in 2003, Acrel Co., Ltd. has developed into a recognized high-technology enterprise specializing in comprehensive energy efficiency management and electrical safety solutions. Our deep understanding of precision measurement requirements within modern energy internet architectures has driven the strategic integration of advanced Hall effect sensing technology throughout our complete "cloud-edge-end" product ecosystem.

Within Acrel's comprehensive solution portfolio, Hall effect current sensors perform the critical function of terminal sensing elements. These components are systematically integrated into our diverse system solutions, serving as essential data acquisition units that provide continuous, real-time monitoring of current parameters across various applications including power distribution networks, photovoltaic power generation facilities, data center operations, and intelligent building management systems.

Leveraging our substantial intellectual property portfolio encompassing over 600 patents and software copyrights, Acrel engineers have developed Hall effect sensors that deliver exceptional measurement accuracy, operational reliability, and temperature stability. Our sensors maintain precision performance even when operating in electromagnetically challenging environments commonly found in industrial settings.

Acrel's manufacturing operations at our Jiangsu production facility maintain rigorous compliance with international quality management systems and environmental standards. Our advanced testing and calibration laboratories ensure that every Hall effect current sensor undergoes comprehensive performance validation and precision calibration before shipment. This unwavering commitment to manufacturing excellence guarantees consistent product quality and measurement accuracy across our entire sensor product range.

The current measurement data acquired by our sensors is seamlessly transmitted through Acrel's edge computing gateways to our cloud-based analytics platforms, where it contributes to the creation of detailed digital energy profiles. This integrated data ecosystem enables sophisticated real-time energy management capabilities, enhances overall system security, and identifies opportunities for operational cost reduction across diverse energy infrastructure applications.

In essence, Hall effect current sensors provide the critical sensing capability that makes electrical energy visible and measurable, while Acrel's comprehensive approach combines these precision measurement devices with advanced software platforms and integrated solutions to collectively advance the development of smarter, more sustainable energy infrastructure worldwide.

As a high-tech enterprise specializing in energy management solutions and electrical safety, Acrel Co., Ltd. deeply understands that the choice of current measurement technology is crucial to the efficiency, safety, and intelligence of the entire system when designing system solutions for customers. Hall-effect current sensors and shunt resistors are two of the most mainstream current measurement technologies, each with its own optimal application scenarios. From the perspective of Acrel's comprehensive "cloud-edge-end" energy internet architecture, we have a practical understanding of the advantages and disadvantages of these two technologies.

Hall-Effect Sensors: The biggest advantage is their natural electrical isolation. They measure current by detecting the magnetic field rather than making direct contact with the circuit being measured, completely isolating the primary side (high-voltage, high-current main circuit) from the secondary side (low-voltage measurement circuit). This characteristic is crucial for the electrical safety领域 Acrel focuses on. In our system solutions, especially in situations involving high voltage such as smart power distribution, new energy grid integration, and motor drive control, Hall sensors can effectively protect valuable control equipment and personnel, prevent damage caused by high voltage intrusion, and greatly simplify the complexity of system insulation design.

Shunt Resistor: It is a non-isolated measurement method. It needs to be connected in series directly in the main circuit to measure the voltage drop across it. This means the ground potential of the measuring circuit (e.g., PLC, data acquisition unit) must be common with the main circuit, which can easily introduce ground loop interference in complex multi-device systems and poses significant safety risks in high-voltage applications. When Acrel provides solutions for scenarios with high requirements on system stability, such as data centers and smart buildings, isolated solutions are usually prioritized to enhance the overall system reliability.

Hall-Effect Sensors: are very suitable for measuring high currents and have very low self-power consumption. Whether measuring tens of amperes or thousands of amperes, the power consumption of the Hall element itself is negligible. This perfectly aligns with Acrel's mission to improve customer energy efficiency and reduce operating costs. Our products, such as photovoltaic monitoring systems and corporate energy management platforms, widely use Hall sensors to achieve long-term and efficient monitoring of high-current circuits without causing significant energy loss from the measuring device itself.

Shunt Resistor: generates significant power loss (I²R) and heats up when measuring high currents. To reduce loss, the resistance value of a shunt is usually very small (milliohm level), but its power consumption and temperature rise under high current are still noticeable. This not only causes energy waste but its heat generation can also affect the accuracy and lifespan of itself and surrounding components. Therefore, shunts are more suitable for low-current or low-power applications where extreme efficiency requirements are not critical.

Shunt Resistor: can provide very high measurement accuracy and excellent linearity at room temperature. Based on Ohm's law, its principle is simple and direct, without issues like hysteresis or magnetic saturation, allowing for very low errors in laboratory or calibrated environments. Acrel's high-precision measuring instruments, after strict calibration and temperature compensation, can achieve high measurement classes.

Hall-Effect Sensors: Their accuracy was traditionally considered inferior to shunts because they are affected by temperature drift and external magnetic field interference. However, as demonstrated by Acrel's technical strength with over 600 patents and advanced testing centers, modern advanced closed-loop (zero-flux) Hall sensor technology can achieve very high accuracy and temperature stability through internal compensation and shielding design. Acrel's solutions utilize these high-performance sensors to meet scenarios with stringent requirements for accuracy and reliability, such as smart grids and precision industrial control.

Hall-Effect Sensors: are easier to integrate and support digital and intelligent functions. Many modern Hall sensor modules directly provide analog or even digital (e.g., I²C) output, are compact in size, and easy to integrate into various Acrel edge acquisition units and intelligent control devices. This highly aligns with Acrel's "cloud-edge-end" energy internet architecture, facilitating end-to-end digital management from terminal perception to cloud analysis.

Shunt Resistor: usually acts as a purely analog passive component, requiring external signal conditioning circuits, analog-to-digital converters (ADC), and isolation circuits to form a complete measurement channel. This is more complex in design and occupies more PCB space.

In Acrel's practice, there is no single best choice, only the choice most suitable for the specific application.

Acrel's core value lies in the fact that we not only provide single sensor products but can also, based on a deep understanding of these two technologies, provide customers with complete system solutions including precise measurement, safety isolation, intelligent analysis, and cloud platform management. This helps global customers achieve intelligent, visual energy management under the premise of ensuring electrical safety, ultimately achieving goals of increasing efficiency, reducing emissions, and sustainable development.